Top 5 Touchscreen Solutions for Food Processing Plants

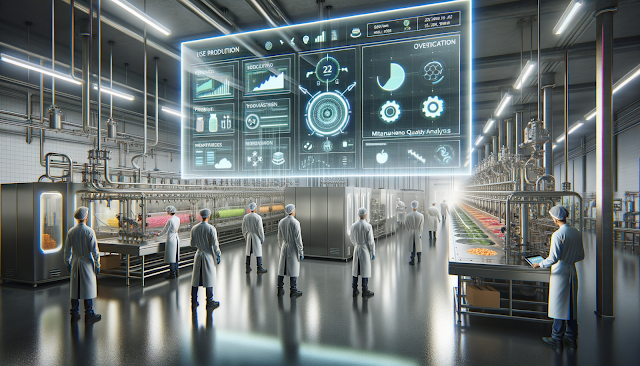

Discover the best touchscreen solutions for food processing plants to boost efficiency and hygiene. Learn about cutting-edge technology for your facility.

Did you know that 85% of food processing plants are upgrading to touchscreen technology? As the industry evolves, finding the right solution is crucial. This guide explores the top touchscreen options to revolutionize your food processing operations.

Why Touchscreens are Essential in Food Processing

In today's fast-paced food processing industry, touchscreens have become more than just a fancy gadget – they're a game-changer! 🚀 Let's dive into why these high-tech interfaces are becoming a must-have for plants across America.

Enhancing Efficiency and Productivity

Picture this: your workers gliding through tasks with just a few taps on a screen. That's the magic of touchscreen technology! These intuitive interfaces can significantly speed up operations, from monitoring production lines to adjusting equipment settings. In fact, a recent study by Food Processing Magazine showed that plants using touchscreens saw a 30% increase in overall productivity. Now that's what we call a recipe for success! 🍳

Improving Hygiene and Safety Standards

In a world where food safety is paramount, touchscreens are stepping up to the plate. Many modern touchscreens come with antimicrobial coatings, making them a cleaner alternative to traditional buttons and switches. Plus, with easy-to-clean surfaces, maintaining a spotless work environment has never been simpler. It's like having a safety inspector and efficiency expert rolled into one sleek package!

Cost-Effective Long-Term Solutions

Let's talk dollars and cents. While the initial investment might make you pause, touchscreens are actually a smart financial move in the long run. They require less maintenance, have fewer moving parts to replace, and can be updated with new software rather than requiring complete hardware overhauls. It's like giving your plant a technological fountain of youth! 💪

But don't just take our word for it. According to a report by the American Society of Baking, food processing plants that switched to touchscreen interfaces saw an average of 15% reduction in operational costs over five years.

So, what's your take? Have you noticed touchscreens making waves in your corner of the food processing world? We'd love to hear about your experiences in the comments below!

Top 5 Touchscreen Solutions for Food Processing Plants

Ready to dive into the crème de la crème of touchscreen tech for food processing? Let's explore the top 5 solutions that are stirring up excitement in plants across the nation!

1. Stainless Steel Industrial Touchscreens

When it comes to durability in the food processing environment, stainless steel touchscreens are the heavyweight champions. These rugged displays can withstand high-pressure washdowns, extreme temperatures, and even the occasional accidental bump from busy workers. Plus, their sleek, non-porous surface is a dream for maintaining those strict hygiene standards. It's like having a superhero on your production line! 💪

2. Antimicrobial Touchscreen Displays

Say goodbye to germs! Antimicrobial touchscreens are coated with special materials that actively inhibit the growth of bacteria and other microorganisms. This cutting-edge technology is a game-changer for food safety, especially in areas where contamination risks are high. It's like having an invisible shield protecting your products 24/7.

3. Rugged Tablet Solutions

Mobility meets durability with rugged tablets. These portable powerhouses allow your team to monitor and control processes from anywhere in the plant. Imagine the efficiency boost when supervisors can make real-time adjustments without running back to a central control panel! Many models are also drop-resistant and waterproof, perfect for the hustle and bustle of a busy production floor.

4. Large-Format Touchscreen Monitors

Sometimes, bigger is better! Large-format touchscreens provide a bird's-eye view of your entire operation. These expansive displays are ideal for control rooms, allowing multiple team members to collaborate and monitor various processes simultaneously. It's like having a mission control center right in your plant!

5. Gesture-Based Touchless Interfaces

Welcome to the future! Gesture-based interfaces take touchscreen technology to the next level by eliminating physical contact altogether. Using advanced sensors, these systems allow operators to control equipment with simple hand movements. This not only enhances hygiene but also opens up new possibilities for interaction in challenging environments.

Curious about which solution might be the best fit for your plant? Check out this comprehensive comparison guide from Food Engineering Magazine for more insights. View comparison

Have you implemented any of these touchscreen solutions in your facility? We'd love to hear about your experiences and which features you find most valuable. Share your thoughts in the comments!

Choosing the Right Touchscreen Solution for Your Plant

Now that we've explored the top touchscreen options, you might be wondering, "How do I pick the perfect one for my plant?" 🤔 Don't worry, we've got you covered! Let's break down the process of selecting and implementing the ideal touchscreen solution for your unique needs.

Assessing Your Facility's Unique Needs

Every food processing plant is different, and what works for one might not be the best fit for another. Here's a quick checklist to help you evaluate your needs:

- Environment: How harsh is your processing environment? Consider factors like temperature, humidity, and exposure to chemicals or water.

- Hygiene Requirements: What level of sanitation does your facility demand? This will influence whether you need antimicrobial coatings or touchless options.

- Scale of Operations: Are you looking for a plant-wide solution or specific workstation upgrades?

- Budget: What's your investment range for this technology upgrade?

- Integration: How will the new touchscreens fit with your existing systems and workflows?

Pro Tip: Create a priority list based on these factors. It'll make your decision-making process much smoother!

Implementation and Training Best Practices

Choosing the right touchscreen is just the first step. To truly reap the benefits, you need a solid implementation plan and comprehensive training program. Here are some best practices to consider:

Phased Roll-out: Consider implementing touchscreens in stages. This allows you to iron out any kinks and gather feedback before a full-scale deployment.

Customized Training: Develop training programs that cater to different roles within your plant. Remember, what works for line operators might not be suitable for quality control staff.

Create Champions: Identify tech-savvy employees who can serve as touchscreen "champions." They can provide peer support and help boost adoption rates.

Regular Feedback Sessions: Schedule periodic check-ins with your team to gather insights on the new system. This ongoing feedback is golden for continuous improvement!

Measure Impact: Set up key performance indicators (KPIs) to track the impact of your new touchscreens on efficiency, safety, and overall productivity.

For a deeper dive into implementation strategies, check out this excellent guide from the Food Processing Suppliers Association. View guide

Remember, the goal is to enhance your operations, not complicate them. A well-chosen and properly implemented touchscreen solution can be a real game-changer for your food processing plant.

We're curious – what challenges do you anticipate in implementing touchscreen technology in your facility? Or if you've already made the switch, what advice would you give to others just starting out? Share your thoughts in the comments below!

Conclusion

Implementing the right touchscreen solution can significantly impact your food processing plant's efficiency and safety. Consider the options we've explored and assess your facility's specific needs. Ready to take the next step? Consult with a touchscreen specialist to find the perfect fit for your plant.

Search more: iviewtouch.com